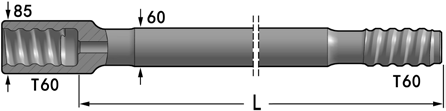

Bench and long-hole drilling T60 (2 3/8″)

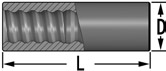

Extension pole, extension rod, extension handle

Threaded Connection: R32, R38, T38, T45, T51, and so on.

Diameter: OD32, OD38, HEX32, HEX35, And so on.

Length: 800-6000MM.

Package: Wood case or wrapped with plastic knitting and then packed into bundles or as per your requests.

Bench and long-hole drilling T60 (2 3/8″)

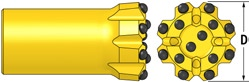

| Bits |

Diameter |

Buttons,mm |

Angle |

Flushing hole |

Weight approx kg |

Part No. |

||||||

|

mm |

in |

Front No Size |

Gauge No Size |

Type |

Front |

Gauge |

||||||

| Button bit | ||||||||||||

|

92 |

3 5/8” |

6×12 |

8×14 |

|

35º |

4 |

- |

5.2 |

1433-92T60-612/814-45-41 |

||

|

96 |

3 3/4” |

6×12 |

8×14 |

|

35º |

4 |

- |

5.3 |

1433-96T60-612/814-45-41 |

|||

|

102 |

4” |

6×13 |

8×13 |

|

35º |

4 |

- |

6.4 |

1433-102T60-613/813-45-41 |

|||

|

115 |

4 1/2” |

6×13 |

8×14 |

|

35º |

4 |

- |

7.3 |

1433-115T60-613/814-45-41 |

|||

|

115 |

4 1/2” |

6×13 |

8×14 |

|

35º |

4 |

- |

7.3 |

1433-115T60-613/814-45-51 |

|||

|

127 |

5” |

7×14 |

8×16 |

|

35º |

4 |

- |

8.9 |

1433-127T60-714/816-45-41 |

||

|

140 |

5 1/2” |

7×16 |

8×16 |

|

35º |

4 |

- |

12.1 |

1433-140T60-716/816-45-41 |

|||

|

152 |

6” |

7×16 |

8×16 |

|

35º |

4 |

- |

13.6 |

1433-152T60-716/816-45-41 |

|||

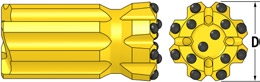

| Button bit, Retrac | ||||||||||

|

92 |

3 5/8” |

6×12 |

8×14 |

|

35º |

4 |

- |

6.1 |

1533-92T60-612/814-45-41 |

|

96 |

3 3/4” |

6×12 |

8×14 |

|

35º |

4 |

- |

6.2 |

1533-96T60-612/814-45-41 |

|

|

102 |

4” |

6×13 |

8×13 |

|

35º |

4 |

- |

8.0 |

1533-102T60-613/813-45-41 |

|

|

115 |

4 1/2” |

6×13 |

8×14 |

|

35º |

4 |

- |

9.4 |

1533-115T60-613/814-45-41 |

|

|

115 |

4 1/2” |

6×13 |

8×14 |

|

35º |

4 |

- |

9.4 |

1533-115T60-613/814-45-51 |

|

|

127 |

5” |

7×14 |

8×16 |

|

35º |

4 |

- |

13.1 |

1533-127T60-714/816-45-41 |

|

140 |

5 1/2” |

7×16 |

8×16 |

|

35º |

4 |

- |

16.1 |

1533-140T60-716/816-45-41 |

|

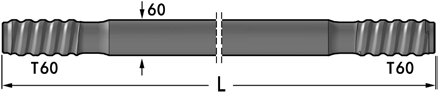

| Rods |

Length |

Diameter |

Weight approx kg |

Part No. |

||

|

mm |

ft/in |

mm |

inch |

|||

| MF-rod, T60-Round60-T60 | ||||||

|

3660 |

12' |

60 |

2 3/8” |

70.0 |

24R60-T60-3660-23 |

|

4270 |

14' |

60 |

2 3/8” |

82.0 |

24R60-T60-4270-23 |

|

|

6100 |

20' |

60 |

2 3/8” |

116.0 |

24R60-T60-6100-23 |

|

| MF-rod, T60-Round60-T60 | ||||||

|

4270 |

14' |

60 |

2 3/8” |

86.6 |

24R60-T60/85-4270-23 |

| Coupling sleeve | |||||||

|

T60 |

315 |

1 3/8” |

85 |

3 11/32” |

7.9 |

31-T60-85-315-23 |

|

T60 |

315 |

1 3/8” |

89 |

3 1/2” |

8.2 |

31-T60-89-315-23 |

|

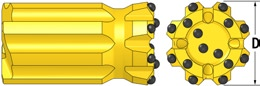

Extension rod, other names are Extension drill steel, Extension drill rod, and Extension steel, M/F rod ( Speedrod ) , Produce Hexagonal and round cross sections, Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter than hexagonal rods and are normally used in extension drilling applications. With the longer steel tending to be larger in diameter, conventional extension steel is characterized by a duplicate thread on each end of the steel.

M/F drill steel is an alternative to couplings sleeves to include the female part of the threaded connection as an integral part of the drill steel. M/F drill steel provides more rigid connections and is easier to uncouple and handle. The service life also tends to be better than with separate couplings.

For Extension Rod and M/F steel process, the below two different types of heat treatment are used to strengthen high speed and powerful percussive drill string components to maximize their performance and reliability.

Carburization is a process used to harden the entire rod surface both internally and externally to strengthen and extend the life of the rod.

High Frequency Induction is a process where only the thread ends of the rod are hardened to lengthen thread life.