-

steel flange flange billet carbon steel flange forged flange big steel flange

Product Nameweld neck flange, slip on flange, blind flange, tube sheet, threaded flange,

socket weld flange, plate flange, spectacle blind, LWN, Orifice flange, anchor flange.

(En1092-1 PN10 Pn16 DN900 DN750 Plate Steel Stainless Steel Flange)OD15mm-6000mmPressure150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000StandardANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc.Wall thicknessSCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60,

SCH80, SCH160, XXS and etc.MaterialStainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S,

A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541,

254Mo and etc.

Carbon steel: A105, A350LF2, Q235, St37, St45.8, A42CP, E24 , A515 Gr60, A515 Gr 70Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 ,

UNS32760, 1.4462,1.4410,1.4501 and etc.

Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc.Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,

C22, C-276, Monel400, Alloy20 etc.

Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc.ApplicationPetrochemical industy;avation and aerospace industry;pharmaceutical industry;

gas exhaust;power plant;ship buliding;water treament,etc.Advantagesready stock,faster delivery time;available in all sizes,customized;high quality -

profession steel manufacturer AISI 4140 42CrMo4 42CrMo 1.7225 G41400 alloy hollow round bar

profession steel manufacturer AISI 4140 42CrMo4 42CrMo 1.7225 G41400 alloy hollow round bar price per kg

Surfacebright,pickled,blackTechniqueForged/Hot Rolled/Cold Drawn/PeeledCategory1.Round bar

1)Hot rolled black bar: (5-400)x6000mm or according to your requirement.

2)Acid round bar: (5-400)x6000mm or according to your requirement.

3)Cold drawn bright bar: (1-20)x6000mm or according to your requirement.

4)Polishing round bar: (5-400)x6000mm or according to your requests.2. Square bar

1)Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests.

2)Acid square bar: (5*5-400*400)x6000mm or according to your requests.

3)Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests.

4)Polishing square bar: (5*5-400*400)x6000mm or according to your requests.3. Flat bar

1)Hot rolled flat bar: (3-30)*(10-200mm)*6000mm or according to your requests.

2)Cold drawn flat bar: (3-30)*(10-200mm)*6000mm or according to your requests.4. Hexagon bar

1)Hot rolled hexagon bar: (5-100)x6000mm or according to your requests.

2) Acid hexagon bar: (5-100)x6000mm or according to your requests.

3)Cold drawn hexagon bar: (1-20)x6000mm or according to your requests t.

4)Polishing hexagon bar: (5-100)x6000mm or according to your requests.5. Channel bar

1)Hot rolled channel bar: (5-100)x6000mm or according to your requests.

2)Acid channel bar: (5-100)x6000mm or according to your requests.

3)Cold drawn channel bar: (1-20)x6000mm or according to your requests.6. Threaded bar

1)Hot rolled threaded bar: (5-100)x6000mm or according to your requests.

2)Acid threaded bar: (5-100)x6000mm or according to your requests.

3)Cold drawn threaded bar: (1-20)x6000mm or according to your requests.7. Angle bar

1)Hot rolled angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests

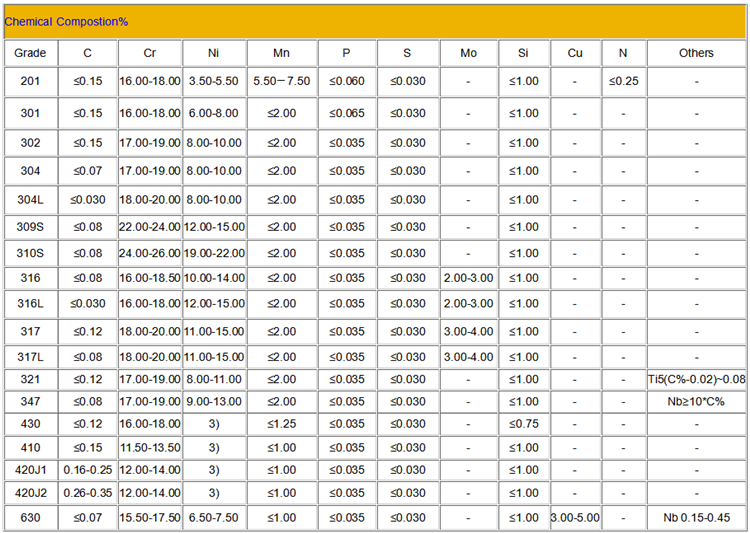

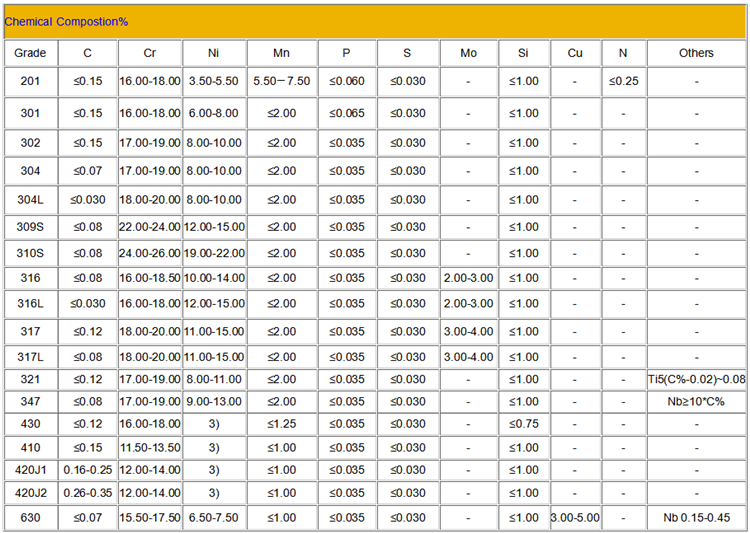

2)Acid angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests.3)Cold drawn angle bar: (16-200)x(16-200)x(3-18)x(3000-9000)mm or according to your requests.Diameter±H9 tolerance can reach the industry standardProductivity5000 tons/monthStandardGB, AISI/JIS, SUS, UNS, DIN 17440 17220(BS970 Part4)MaterialStainless steel:

200series:201,201L,202,202cu,204

300series:301,302,303,304,304L,309,309s,310,310S,310H,316,316L,317,316Ti,317L,321,321H,347,329,330 etc

400series:409,409L,410,420,430,431,439,440,441,444,446,403,440A,440B,440C etc

Others:XM-19,XM27,2906,330,660,630,631,17-4ph,17-7ph, 15-5ph,S318039 904L,etc

Duplex stainless steel:2205,2507,S22053,S25073,S22253,S31803,S32205,S32304

Special Stainless Steel:904L,253MA,347/347H,317/317L,316Ti,254SMO,AL-6XN,S31050,U3,HD,C4,DS-2,69111,s45000 etc

Alloy:

Hastelloy: hastelloyB3/B2/X/C/C22/C276/G-30

Inconel: inconel600/625/718/725,

Incoloy: incoloy800/800h/825/925,

Monel: monel400/k500/404,

Nickel: nickel200/201,

Nitronic: Nitronic50/60,

Alloy: Alloy20/28/330/31/33/75, 4J36/1J50/1J79/4J29/4J42,/3J53

Nimonic: nimonic80/80a/90/75, etc -

27simn hydraulic cylinder pipe steel Hollow bar and hollow drill rod and hollow drill bar

Commodity: hollow bar

27simn hydraulic cylinder pipe

Grade: ST52, E355,C45E,25CrMo4,34CrMo4,42CrMo4,CK45,E410,E470,20MnV6,S45C,SAE1020,SAE1026,SAE1045,SAE1541, SAE4130,SAE40,SAE4145,SAE4340,etc.

Size range: 60mm*40mm-460mm*420mm.

Manufacture method: hydraulic cold drawn,cold rolled,hot rolled+deep hole drilled/deep hole bored.

Delivery condition:

BK BKW BKS GBK NBK Q+T +C +LC +SR +A +N Q+T CW/hard CW/soft Stress relieved Annealed Normalized Quenched+Tempered Machining,turning,hard chrome plating,grinding,deep hole boring,skiving&roller burnishing services are available.

End finish: plain ends with suqare cuts,free of burrs, bevelled ends.

-

ASTM A106 GR.B A53 GR.B Black Carbon Seamless Steel Pipe And Tube rectangular pipe

Product DescriptionStandardASTM A106, ASTM A53, API 5L Gr.B, DIN17175,DIN1629MaterialASTM A106B, ASTM A53B, API 5L Gr.B,ST52, ST37,ST44

SAE1010/1020/1045,S45C/CK45,SCM435,AISI4130/4140Outer diameter13.7mm-609.6mmWall thickness1.5mm-50mmLength3m-12m, random or fixed, as the clients’ requestsTechnologyHot RolledToleranceControl with in the standard, OD:+/-1%, WT:+/-5%Advantages1.Short delivery time2.Quality assurance3.Competitive price4.Free SampleASTM A106 GR.B A53 GR.B Black Carbon Seamless Steel PipeAccording to the material,the pipes can divide into Carbon Steel Seamless Pipes and Alloy Steel Seamless Pipes.For carbon steel seamless pipes,the mechanical property is much lower than alloy steel materials.Especially the tensile strength and yield strength.

So carbon steel pipes mainly used in transport petroleum,oil,gas and construction material.But alloy steel pipes can widely used in high pressure boiler system,heat exchanger,mechanical property. -

seamless steel rectangular section

seamless steel rectangular section

hollow section,solid section

-

custom Bicycle forks 4130 crmo material alloy small diameter seamless steel tube

4130 Alloy Chromoly Steel Pipe

Chemical Composition(%) Mechanical Property C Si Mn S P Cr Ni Cu Mo Yield Strength Tensile Strength ( σs ) ( σb ) 0.28~0.33 0.15~0.30 0.40~0.60 ≤0.04 ≤0.035 ≤0.15 0.80~1.10 / 0.15~0.25 ≥785(80)

(MPa)≥930(95) (MPa) End Shape Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer’s requirements Surface Oiled, Galvanized, Phosphate etc Treatment Technique Cold drawn Application 1. Automotive and mechanical pipes 2. Petroleum cracking pipes 3. High Pressure Boiler Pipe 4. Low and middle pressure fluid transportation pipeline 5. Chemical fertilizer equipment pipes 6. Heat exchanger pipes Delivery 1. BK (+C) No heat treatment after last cold forming process. Conditions 2. BKW (+LC) After last heat treatment there is a light finishing pass (cold drawing) 3. BKS (+SR) After the final cold forming process the tubes are stress relieve annealed. 4. GBK (+A) After the final cold forming process the tubes are annealed in a controlled atmosphere. 5. NBK (+N) After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere. Package 1. Bundle Packing. 2. Plain end or vanished as per customer’s request. 3. Wrapped in waterproof paper. 4. Sackcloth with several steel strips. 5. Pack in heavy tri-wall boxes -

customized Octagonal/ Hexagon/Oval special shaped seamless steel pipe steel tube hollow bar

Q: Are you Manufacturer or Trading Company?

A: We are factory of Special Shaped Steel Pipe since 2010Q: What’s Kinds of Special Shaped Pipe produced?A: Oval steel pipe.Trapezoidal steel pipe,Concave steel pipe,Sector steel pipe,Hexagonal steel pipe,Plum blossom Steel Pipe,Tunnel steel pipe,L Shaped Steel Pipe,D Shaped Steel Pipe etcQ:What’s your payment?A:We accept TT and LC paymentQ: Do you have any promotions?A:Yes, we have promotions all times as following:50% TT deposit and the balance will be paid before delivery, promotions is $7/Ton100% TT deposit , promotions is $15/Ton -

12L14 11SMnPb30 SUM24L Cold Drawn Free Cutting Steel Round Bar cutted steel round bar

12L14 11SMnPb30 SUM24L Cold Drawn Free Cutting Steel Round Bar

1. Chemical composition(%):

C Si Mn P S Pb ≤0.15% ≤0.15% 0.85-1.15% 0.04-0.09% 0.26-0.35% 0.15-0.35% 2. Equivalent Steel Grade:

DIN ASTM GB EN / ISO JIS UNS 1.0718 12L14 Y12Pb Y15Pb

11SMnPb28 11SMnPb30

SUM24L G12144 3. Charateristics:

12L14 bar is a standard resulfurized and rephosphorized grade carbon Steel, and a free machining steel. The added lead to the chemical composition provides improved machinability. Although the machinability is very good, the added lead content reduces the overall strength of this alloy.

-

ST 52 Steel Pipe Hollow Bar ST 52.0 ST 52.3 E355 Seamless Tube Stainless Steel Tube ASTM 316 201 Square Pipe China factory SS

Stainless Steel Tube ASTM 316 201 Square Pipe China factory SSProduct NameSquare / Rectangle Stainless Steel Pipe,Stainless Steel TubeSurfaceN0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etcMaterial201,202,301,302,303,304,304L,304N1,309S,310S,316,316L,316Ti,316N,317,317L,321,409L,410,420,430,904,904L,etcGrade200/300/400/500/600/700/800/900 series/duplex stainless steelStandardsAISI ASTM JIS SUS DIN GBCertificationsISO 9001 and SGSPackingIndustry standard packaging or according to client’s requirementPlace of originJiangsu China(mainland)BrandJBRPaymentT/T,L/C,Western Union,Paypal,Apple Pay,Google Pay,D/A,D/P,MoneyGramDelivery timeUp to order quantity,contact us to know Features of Squrae / Rectangle STAINLESS STEEL PIPE1.Not easily rust, acid resistance and corrosion resistance;

Features of Squrae / Rectangle STAINLESS STEEL PIPE1.Not easily rust, acid resistance and corrosion resistance;

2.Widely used in light industry,heavy industry, daily necessities and the decoration industry;

3.Large and stable supplies, long-term supplies;

4.Prompt delivery, rich exporting experience.Square Tube

Rectangle Tube

Size(mm)

Wall Thickness (mm)

Size(mm)

Wall Thickness (mm)

20*20

25*25

30*30

1.2-3.0

20*40 30*40

1.2-3.0

40*40

50*50

1.2-4.75

30*50 25*50

30*60 40*60

1.2-4.75

70*70 75*75

80*80 90*90

100*100

1.5-5.75

60*80 50*80

100*40 120*80

1.5-5.75

120*120 140*140

150*150

2.5-10.0

160*80 100*150

140*80 100*180

200*100

2.5-10.0

160*160 180*180

200*200

3.5-12.0

200*150 250*150

3.5-12.0

250*250 300*300

350*350

4.5-15.75

250*200 300*200

350*200 350*250

450*250 400*300

500*200

4.5-15.75

280*280

400*400

5.0-20.0

400*350 400*250

500*250 500*300

400*600

5.0-20.0

-

St52 alloy seamless steel hollow bar

ST 52 Steel Pipe Hollow Bar ST 52.0 ST 52.3 E355 Seamless Tube

ST52 Alloy Steel Pipe Tube

Chemical Composition(%) Mechanical Property C Si Mn S P Cr Ni Cu Mo Yield Strength Tensile Strength ( σs ) ( σb ) 0.12~0.20 0.20~0.55 1.20~1.60 ≤0.04 ≤0.35 ≤0.30 275~345 (MPa) 470~660 (MPa) End Shape Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer’s requirements Surface Oiled, Galvanized, Phosphate etc Treatment Technique Cold drawn Application 1. Automotive and mechanical pipes 2. Petroleum cracking pipes 3. High Pressure Boiler Pipe 4. Low and middle pressure fluid transportation pipeline 5. Chemical fertilizer equipment pipes 6. Heat exchanger pipes Delivery 1. BK (+C) No heat treatment after last cold forming process. Conditions 2. BKW (+LC) After last heat treatment there is a light finishing pass (cold drawing) 3. BKS (+SR) After the final cold forming process the tubes are stress relieve annealed. 4. GBK (+A) After the final cold forming process the tubes are annealed in a controlled atmosphere. 5. NBK (+N) After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere. Package 1. Bundle Packing. 2. Plain end or vanished as per customer’s request. 3. Wrapped in waterproof paper. 4. Sackcloth with several steel strips. 5. Pack in heavy tri-wall boxes.

Hello, come to consult our products !